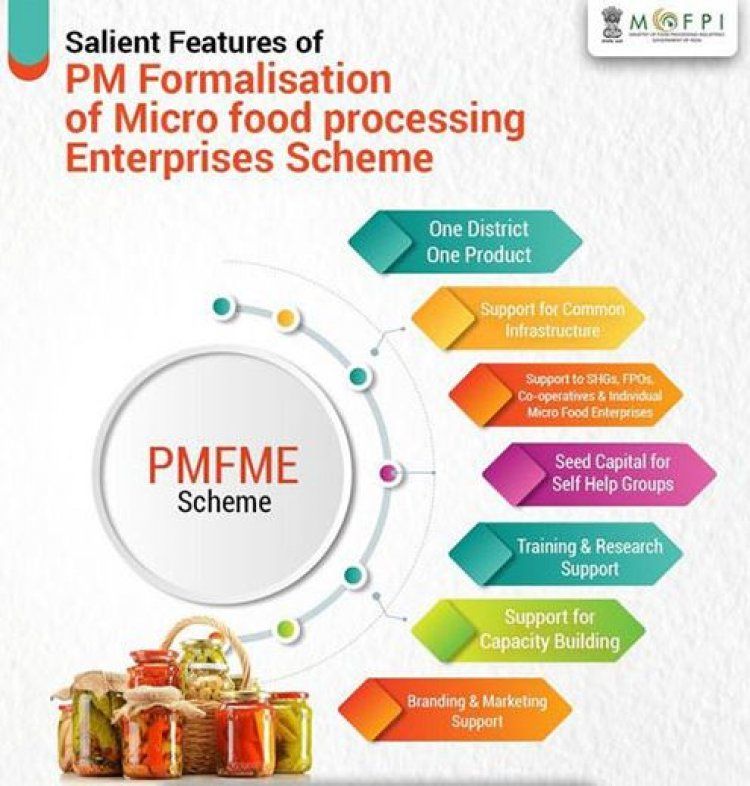

The Ministry of Food Processing Industries (MoFPI) has introduced the PM Formalisation of Micro Food Processing Enterprises (PM-FME) Scheme under the Atmanirbhar Bharat Abhiyan to strengthen India’s food processing sector at the grassroots level. The scheme aims to support micro food entrepreneurs by encouraging value addition, improving processing practices, reducing post-harvest losses, and enabling informal units to grow into sustainable enterprises.

Recently, I had the opportunity to participate in a session conducted by NIFTEM-T, Thanjavur, for farmers and Farmer Producer Organisations (FPOs). The session focused on value addition of agricultural crops and provided practical insights into the PM-FME scheme. Through this interaction, the scope of the scheme and its real-world relevance became much clearer.

During the session, it was emphasized that the PM-FME scheme is not limited to specific products. Instead, it supports a wide range of food processing activities based on local resources and regional strengths, following the One District One Product (ODOP) approach.

The following examples, discussed during the session and classroom learning, help illustrate the scheme’s scope.

1)Value Addition in Frozen Vegetables – Example of Cauliflower

Frozen vegetables are gaining importance due to their convenience, extended shelf life, and ability to reduce post-harvest losses. Cauliflower is one such vegetable with strong value-addition potential.

a) Harvest and Primary Handling

- Crop duration: 90 to 120 days

- At harvest, the cauliflower head is cut and visible debris is removed.

b) Processing Steps

- Washing to remove soil and impurities

- Trimming and cutting into florets

- Trimming and cutting into florets

Blanching to retain colour, texture, and nutritional quality - Drying and cooling before freezing

- Drying and cooling before freezing

Freezing using IQF (Individually Quick Frozen) technology, which maintains product quality and allows free-flowing florets

c) Packaging and Use

The frozen florets are packed in food grade gauge polythene bags using dry packing or tray packing methods. These products are commonly used in ready to cook foods, ready made meals, and institutional kitchens.

2) Mustard Oil Processing – Example of Oilseed Value Addition

Mustard oil is widely consumed across India and is valued for its spicy aroma and strong flavour.

Processing Overview

- Mustard seeds are used as raw material

- Seeds are cleaned and dried

- The mustard is ground, and oil is extracted using traditional or mechanical methods

- The oil is filtered and prepared for consumption

This example demonstrates how PM-FME supports oilseed-based processing units that are closely linked to regional food habits.

3) Value Addition in Groundnut Products

Groundnut, believed to have originated in South America in the 16th century, is an important crop in India with significant scope for value addition.

Processing Steps

- Cleaning, grading, and sorting

- Drying

- Oil extraction using: High-temperature pressing method or Cold-pressing method, which helps retain nutrients and flavour

What the Session Highlighted about PM-FME

The examples discussed during the NIFTEM-T Thanjavur session like frozen cauliflower, mustard oil, and groundnut products represent different segments of food processing such as vegetables, oilseeds, and traditional foods. Together, they clearly show that the PM-FME scheme is product agnostic and encourages enterprises based on locally available crops and market demand, especially through FPO led initiatives.

Conclusion

The session conducted by NIFTEM-T, Thanjavur, provided valuable practical exposure to how the PM-FME scheme can be implemented at the farmer and FPO level. It reinforced the idea that value addition is not limited to large industries but is achievable even at the micro enterprise level with the right guidance and support.

By integrating traditional practices with modern processing techniques, PM-FME strengthens rural livelihoods, reduces post harvest losses, and promotes entrepreneurship. Overall, the scheme plays a key role in building a self-reliant, sustainable, and inclusive food processing ecosystem in India, benefiting farmers, FPOs, and rural communities alike.