Author: Sibani Singh, JSWFF, Paradeep, Odisha

Co-Author: Anusha Murali, JSWFF, Dolvi, Maharashtra

The travel workshop at Khamir officially began on the 29th of January 2025, but curiosity knows no bounds. Eager to immerse ourselves in the essence of this vibrant craft hub, my co-fellow Anusha and I, along with fellow explorers Rutuja, Manjunath, Arathi, and Nutan, began our journey on Day Zero itself. The air buzzed with creativity as we wandered through the campus, engaging in impromptu conversations with weavers, designers, shop managers, workers, and artisans. Each interaction sparked a thought—how did the traditional techniques here compare to those in our respective project locations? Were the machines there as traditional, or had they evolved with modern technology?

Among the many visitors at Khamir, we noticed designers, students learning various crafts, and art enthusiasts lost in admiration. The scorching sun bore down on us as we soaked in every sight, sound, and story. As the day drew to a close, we were treated to a sumptuous traditional meal prepared by Manish Bhai and his culinary team, served with warmth by Danji Bhai. The flavors of Kutch, rich and authentic, left an unforgettable imprint on our taste buds.

Day 1: Immersing in Tradition and Knowledge

The first official day commenced with a soulful prayer—Daya Kar Daan Vidya Ka Humein Paramatma Dena, sung in unison by fellows from 12 different states alongside Khamir’s dedicated staff. The harmony of voices set the tone for a day steeped in learning. Our guide, the charismatic Aziz Bhai, a textile expert at Khamir, welcomed us with infectious enthusiasm. His deep knowledge of the organization’s history, work culture, and processes unfolded like a living storybook before us.

Khamir’s roots trace back to the devastating 2001 earthquake that shook Gujarat. Organizations like the Red Cross and Abhiyan rushed in to address health and livelihood concerns, particularly in the worst-hit areas of Dhamad and Anjar. What began as the Craft Resource Center (CRC), an informal setup, evolved in 2004 when the Nehru Organization of Abhiyan initiated infrastructural work. They focused on weaving and Ajrakh printing, gradually expanding into leatherwork, pottery, and embroidery. Khamir now serves as a bridge between artisans and the market, empowering them by ensuring direct access to buyers.

Preserving Heritage and Reviving Traditions

Kutch has long upheld the tradition of community-specific craftsmanship. The Marwada community carries forward the legacy of weaving, preserving both skills and machinery. However, industrialization brought challenges—once abundant black cotton, considered the region’s ‘diamond,’ began to vanish due to the monopoly of hybrid seeds and the overuse of chemical fertilizers. Recognizing this crisis, the Lodi, Aahir, and Patel communities united to revive black cotton cultivation. By preserving seeds for future cropping cycles, they restored a crucial part of their agricultural heritage.

The Darbar community, historically involved in Bandhani (tie-dye) work, continues hand-spinning in Kutch. In 2008, the Satvik organization, led by Mira Ben and Ghatit Bhai, stepped in to refine and structure these efforts further. The local term for black cotton, “Kalu”—kalu pholne ja rahe hai—resonates deeply, symbolizing not just material but also cultural identity.

Khadi, often misunderstood, holds profound philosophical significance. True khadi is defined not by the fabric type but by the method—hand-spun and handwoven. The entire dyeing process at Khamir remains natural: turmeric for yellow, katha for brown, rust oxidation for black, manjistha for pink, and alizarin extracted from Aal tree roots for a striking red. Before dyeing, fabrics are treated with alum to ensure color fastness.

The Weaving Process: A Labor of Love

The cost of each fabric piece is determined by the Agricultural Produce Market Committee (APMC), ensuring fair pricing. The weaving process follows meticulous steps:

- Amber Charkha – Costing around ₹18,000, this versatile spinning wheel functions manually and with a motor. A single thread undergoes 20 twists before being deemed finished, producing 1-2 kg of yarn per hour, priced at ₹130/kg.

- Peticharkha – A miniature version of the Amber Charkha, demanding immense patience and skill.

- Carding – The removal of dirt and debris from raw cotton.

- Circular Khadi Spinning – Conducted at Sundarnagar Unit.

The concept of Reyan—a shared space for intergenerational learning—fosters cultural exchange, allowing children, adults, and elders to engage in storytelling and skill-sharing.

Education: Bridging Generations through Art

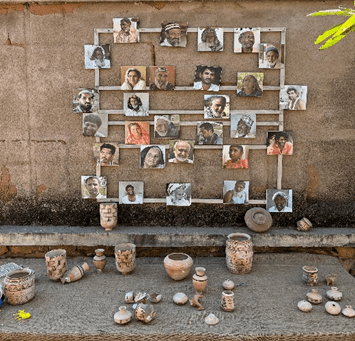

As the sun began to set, we met Ms. Shubhadra and Mr. Rishikesh, dedicated educators who have been working at Khamir for the past three years. Their program, initiated in 2018, integrates traditional crafts into school curriculums. By teaching children pottery, for instance, they seamlessly introduce scientific concepts like force, pressure, and friction. This innovative approach not only preserves art but also instills pride in their ancestral heritage. Regular art fairs and interactive workshops keep the legacy alive, ensuring that future generations cherish their cultural roots.

A Thoughtful Conclusion

As we reflected on the day’s experiences, a deep sense of admiration filled our hearts. Khamir is not merely a craft center—it is a living, breathing testament to resilience, tradition, and innovation. It weaves together the past and present, empowering artisans while educating the youth. This journey was more than an exploration; it was a window into a world where art is not just livelihood but life itself.

Our journey had just begun, but the stories, skills, and spirits we encountered at Khamir would stay with us forever, inspiring us to reimagine sustainability and craftsmanship in our own communities.